错误代码: ●13.B2.Az | ●13.B2.A1 | ●13.B2.A2 |●13.B2.A3 |●13.B2.A4 | ●13.B2.AD | 惠普5系激光打印机 故障代码 其他系列也可以参考 | 二〇二一年五月二十七日

2025-08-09

错误代码: ●13.B2.Az | ●13.B2.A1 | ●13.B2.A2

|●13.B2.A3 |●13.B2.A4 | ●13.B2.AD | 惠普5系激光打印机 故障代码 其他系列也可以参考 |

二〇二一年五月二十七日

--------------------------------------------------

技术热线:朱师傅整理

--------------------------------------------------

中文译本:

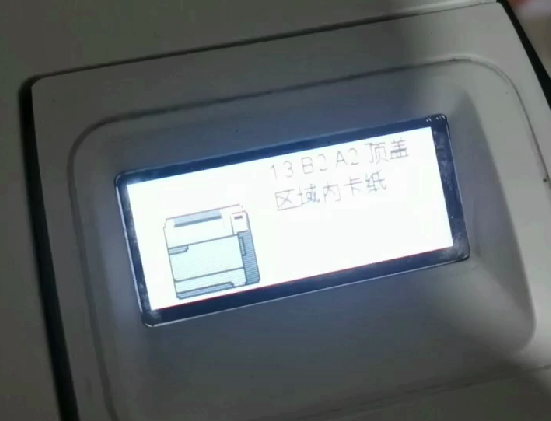

13.B2.Az卡塞在右门描述

介质停留在图像区域的顶盖中。

经过指定的时间限制后,纸张出现在SR6

●13.B2.A1

当介质存在的时间超过“预期介质长度加50毫米”或更长时,就会发生卡纸

从纸盘1打印时,在对位传感器(SR6)上检测到。

●13.B2.A2

当介质的存在时间超过“预期介质长度加50毫米”或更长时,就会发生卡纸

从纸盘2打印时,在对位传感器(SR6)上检测到了错误。

●13.B2.A3

当介质存在的时间超过“预期介质长度加50毫米”或更长时,就会发生卡纸

从纸盘3打印时,在对位传感器(SR6)上检测到了错误。

●13.B2.A4

当介质存在的时间超过“预期介质长度加50毫米”或更长时,就会发生卡纸

当从纸盘4打印时,在对位传感器SR6处检测到)。

●13.B2.AD

当介质存在的时间超过“预期介质长度加50毫米”或更长时,就会发生卡纸

从双面打印器进行打印时,在对位传感器(SR6)处检测到错误。

建议操作

1.打开右上门,检查进纸区域是否有卡纸。

2.测试页面顶部传感器(SR6),确保其自由移动。

3.检查转印区域的ITB和T2滚筒,确保所有物品都正确就位,并且没有

损坏的零件。

4.确保您使用的介质的类型和质量符合HP规格。

5.打开以下菜单:

●行政

●故障排除

●诊断测试

6.使用纸盘/纸箱手动传感器测试来测试配准传感器测试(TOP传感器)(SR6),以验证

传感器功能正常。如果没有,请更换定位组件。

7.测试介质宽度传感器SR13和SR14,如果有缺陷,请更换定位组件。

8.如果传感器正常运行,请运行几页以检查纸张前端实际位于何处

停止。

ZHCN故障排除工具223

从www.Manualslib.com手册搜索引擎下载9。测试定位组件,并检查直流控制器上的连接器J118和J16。

10.如果任何测试表明零件有缺陷,请更换适当的组件。

--------------------------------------------------

英文解释:

13.B2.Az Jam in Right

door

Description

Media STAY jam in top cover at image area.

Paper present at SR6 after specified time limit passed

● 13.B2.A1

This jam occurs when the media is present longer than "the expected media length plus 50mm" or more

is detected at the Registration sensor (SR6) when printing from the Tray 1.

● 13.B2.A2

This jam occurs when the media is present longer than" the expected media length plus 50mm" or more

is detected at the Registration sensor (SR6) when printing from the Tray 2.

● 13.B2.A3

This jam occurs when the media is present longer than "the expected media length plus 50mm" or more

is detected at the Registration sensor (SR6) when printing from the Tray 3.

● 13.B2.A4

This jam occurs when the media is present longer than "the expected media length plus 50mm" or more

is detected at the Registration sensor SR6) when printing from the Tray 4.

● 13.B2.AD

This jam occurs when the media is present longer than "the expected media length plus 50mm" or more

is detected at the Registration sensor (SR6) when printing from the Duplexer.

Recommended action

1. Open upper right door and check for media jammed in feed area.

2. Test the top of page sensor (SR6) to ensure that it moves freely.

3. Check the ITB and T2 roller at transfer area, make sure everything is properly seated and there are no

damaged parts.

4. Ensure the type and quality of the media that you are using meet HP specifications.

5. Open the following menus:

● Administration

● Troubleshooting

● Diagnostic Tests

6. Test Registration Sensor Test (TOP sensor) (SR6) using the Tray/Bin manual sensor test to verify that the

sensor is functioning correctly. If not replace the Registration assembly.

7. Test the Media Width sensors SR13 and SR14 if defective replace the Registration assembly.

8. If sensor functioning properly, run a few pages to check where the leading edge of the paper actually

stops.

ENWW Tools for troubleshooting 223

Downloaded from www.Manualslib.com manuals search engine

9. Test the registration assembly and check connectors J118 and J16 on the DC Controller.

10. If any test shows defective part replace the appropriate assembly.

Description

Media STAY jam in top cover at image area.

Paper present at SR6 after specified time limit passed

● 13.B2.A1

This jam occurs when the media is present longer than "the expected media length plus 50mm" or more

is detected at the Registration sensor (SR6) when printing from the Tray 1.

● 13.B2.A2

This jam occurs when the media is present longer than" the expected media length plus 50mm" or more

is detected at the Registration sensor (SR6) when printing from the Tray 2.

● 13.B2.A3

This jam occurs when the media is present longer than "the expected media length plus 50mm" or more

is detected at the Registration sensor (SR6) when printing from the Tray 3.

● 13.B2.A4

This jam occurs when the media is present longer than "the expected media length plus 50mm" or more

is detected at the Registration sensor SR6) when printing from the Tray 4.

● 13.B2.AD

This jam occurs when the media is present longer than "the expected media length plus 50mm" or more

is detected at the Registration sensor (SR6) when printing from the Duplexer.

Recommended action

1. Open upper right door and check for media jammed in feed area.

2. Test the top of page sensor (SR6) to ensure that it moves freely.

3. Check the ITB and T2 roller at transfer area, make sure everything is properly seated and there are no

damaged parts.

4. Ensure the type and quality of the media that you are using meet HP specifications.

5. Open the following menus:

● Administration

● Troubleshooting

● Diagnostic Tests

6. Test Registration Sensor Test (TOP sensor) (SR6) using the Tray/Bin manual sensor test to verify that the

sensor is functioning correctly. If not replace the Registration assembly.

7. Test the Media Width sensors SR13 and SR14 if defective replace the Registration assembly.

8. If sensor functioning properly, run a few pages to check where the leading edge of the paper actually

stops.

ENWW Tools for troubleshooting 223

Downloaded from www.Manualslib.com manuals search engine

9. Test the registration assembly and check connectors J118 and J16 on the DC Controller.

10. If any test shows defective part replace the appropriate assembly.

--------------------------------------------------

实际故障案例

3】故障案例:

--------------------------------------------------

2】故障案例:

--------------------------------------------------

1】

故障案例:惠普激光打印机报错 13.b2.a2 顶盖区域内卡纸 | h15170345348 | 二〇二五年五月十六日

1、进纸传感器故障

2、进纸离合器故障

3、对位传感器故障

4、对位离合器故障

等待反馈结果:

扫描开通重新登录查看更多

添加朱师傅微信咨询