错误代码: 13.B2.Dz | ●13.B2.D1 | ●13.B2.D2 | ●13.B2.D3 | ●13.B2.D4 | ●13.B2.DD | 惠普5系激光打印机 故障代码 其他系列也可以参考 | 二〇二一年五月二十七日

2021-06-01

错误代码: 13.B2.Dz | ●13.B2.D1 | ●13.B2.D2

| ●13.B2.D3 | ●13.B2.D4 | ●13.B2.DD | 惠普5系激光打印机 故障代码 其他系列也可以参考 |

二〇二一年五月二十七日

--------------------------------------------------

技术热线:朱师傅整理

--------------------------------------------------

中文译本:

13.B2.Dz卡在右门

描述

介质延迟卡在图像区域的顶盖中。

纸张在指定时间内未达到SR6。

●13.B2.D1

在从纸盘1打印的指定时间内,介质没有到达对位传感器。

●13.B2.D2

在从纸盘2打印的指定时间内,介质没有到达对位传感器。

●13.B2.D3

在从纸盘3打印的指定时间内,介质没有到达对位传感器。

●13.B2.D4

在从纸盘4打印的指定时间内,介质没有到达对位传感器。

●13.B2.DD

在双面打印的指定时间内,介质没有到达对位传感器。

建议操作

1.打开右上门,检查进纸区域是否有卡纸。

224第2章解决问题ZHCN

从www.Manualslib.com手册搜索引擎下载2。对于纸盘1,请确保将纸盘宽度和长度导板设置为正确的纸张尺寸。

安装在进纸匣中,并且进纸匣上方的填充标记上方和进纸匣上的卡舌上没有装满纸盒。

图2-75纸盘1纸张导板

描述

介质延迟卡在图像区域的顶盖中。

纸张在指定时间内未达到SR6。

●13.B2.D1

在从纸盘1打印的指定时间内,介质没有到达对位传感器。

●13.B2.D2

在从纸盘2打印的指定时间内,介质没有到达对位传感器。

●13.B2.D3

在从纸盘3打印的指定时间内,介质没有到达对位传感器。

●13.B2.D4

在从纸盘4打印的指定时间内,介质没有到达对位传感器。

●13.B2.DD

在双面打印的指定时间内,介质没有到达对位传感器。

建议操作

1.打开右上门,检查进纸区域是否有卡纸。

224第2章解决问题ZHCN

从www.Manualslib.com手册搜索引擎下载2。对于纸盘1,请确保将纸盘宽度和长度导板设置为正确的纸张尺寸。

安装在进纸匣中,并且进纸匣上方的填充标记上方和进纸匣上的卡舌上没有装满纸盒。

图2-75纸盘1纸张导板

图2-76纸盘1纸张高度导板

ZHCN故障排除工具225

从www.Manualslib.com手册搜索引擎下载3。对于纸盘2,请确保将纸盘宽度和长度导板设置为正确的纸张尺寸。

安装在进纸匣中,并且进纸匣上方的填充标记上方和进纸匣上的卡舌上没有装满纸盒。

图2-77纸盘2纸张导板

图2-78纸盘2纸张高度导板

4.检查纸盘供纸和分离辊是否磨损,如果发现磨损,请更换。

5.测试页面顶部传感器(SR6)。如果SR6无法正常运行,请更换定位组件。

6.测试定位组件,并检查直流控制器上的连接器J118和J16。

7.根据测试确定更换零件。

226第2章解决问题

--------------------------------------------------

英文解释:

13.B2.Dz Jam in Right

Door

Description

Media delay jam in top cover at image area.

Paper did not reach SR6 in specified time.

● 13.B2.D1

Media did not reach the Registration sensor in the designated amount of time printing from Tray 1.

● 13.B2.D2

Media did not reach the Registration sensor in the designated amount of time printing from Tray 2.

● 13.B2.D3

Media did not reach the Registration sensor in the designated amount of time printing from Tray 3.

● 13.B2.D4

Media did not reach the Registration sensor in the designated amount of time printing from Tray 4.

● 13.B2.DD

Media did not reach the Registration sensor in the designated amount of time printing duplexed.

Recommended action

1. Open upper right door and check for media jammed in feed area.

224 Chapter 2 Solve problems ENWW

Downloaded from www.Manualslib.com manuals search engine

2. For Tray 1, make sure that the tray width and length guides are set to the correct paper size being

installed into the tray and that the tray is not over filled above fill mark and over the tab on the tray.

Figure 2-75 Tray 1 Paper guides

Figure 2-76 Tray 1 Paper height guides

ENWW Tools for troubleshooting 225

Downloaded from www.Manualslib.com manuals search engine

3. For Tray 2, make sure that the tray width and length guides are set to the correct paper size being

installed into the tray and that the tray is not over filled above fill mark and over the tab on the tray.

Figure 2-77 Tray 2 Paper guides

Figure 2-78 Tray 2 Paper height guides

4. Check for worn out Tray Feed and Separation rollers, replace if found worn out.

5. Test the top of page sensor (SR6). If SR6 does not function correctly, replace the Registration assembly.

6. Test the registration assembly and check connectors J118 and J16 on the DC controller.

7. Replace parts as determined by tests.

226 Chapter 2 Solve problems

Description

Media delay jam in top cover at image area.

Paper did not reach SR6 in specified time.

● 13.B2.D1

Media did not reach the Registration sensor in the designated amount of time printing from Tray 1.

● 13.B2.D2

Media did not reach the Registration sensor in the designated amount of time printing from Tray 2.

● 13.B2.D3

Media did not reach the Registration sensor in the designated amount of time printing from Tray 3.

● 13.B2.D4

Media did not reach the Registration sensor in the designated amount of time printing from Tray 4.

● 13.B2.DD

Media did not reach the Registration sensor in the designated amount of time printing duplexed.

Recommended action

1. Open upper right door and check for media jammed in feed area.

224 Chapter 2 Solve problems ENWW

Downloaded from www.Manualslib.com manuals search engine

2. For Tray 1, make sure that the tray width and length guides are set to the correct paper size being

installed into the tray and that the tray is not over filled above fill mark and over the tab on the tray.

Figure 2-75 Tray 1 Paper guides

Figure 2-76 Tray 1 Paper height guides

ENWW Tools for troubleshooting 225

Downloaded from www.Manualslib.com manuals search engine

3. For Tray 2, make sure that the tray width and length guides are set to the correct paper size being

installed into the tray and that the tray is not over filled above fill mark and over the tab on the tray.

Figure 2-77 Tray 2 Paper guides

Figure 2-78 Tray 2 Paper height guides

4. Check for worn out Tray Feed and Separation rollers, replace if found worn out.

5. Test the top of page sensor (SR6). If SR6 does not function correctly, replace the Registration assembly.

6. Test the registration assembly and check connectors J118 and J16 on the DC controller.

7. Replace parts as determined by tests.

226 Chapter 2 Solve problems

--------------------------------------------------

实际故障案例

3】故障案例:

--------------------------------------------------

2】故障案例:

--------------------------------------------------

1】

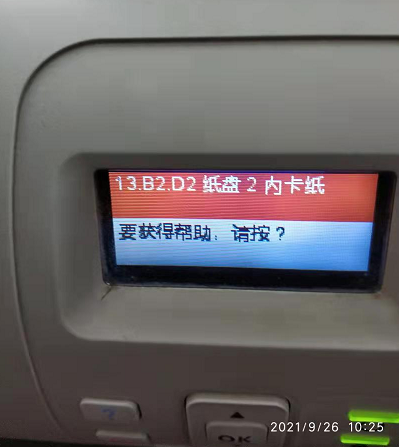

故障案例:惠普m551 报错13.b2.d2纸盘2内卡纸 | 三星晋城李经理 qingtianpilimmm | 二〇二一年十月十八日

●13.B2.D2

在从纸盘2打印的指定时间内,介质没有到达对位传感器。

主要考虑进纸问题 看看搓纸轮 湿抹布擦一下 看看 如果有效看看是不是该换了

在从纸盘2打印的指定时间内,介质没有到达对位传感器。

主要考虑进纸问题 看看搓纸轮 湿抹布擦一下 看看 如果有效看看是不是该换了

等待反馈结果:

扫描开通重新登录查看更多

添加朱师傅微信咨询